I’ve spent >7 years at Meta Real Labs working on nearly every aspect of AR displays, culminating in Orion, Meta Ray Ban Display, and other yet-to-be-revealed AR glasses devices.

Over the years, this has given me a breadth of experience with everything going into AR display systems.

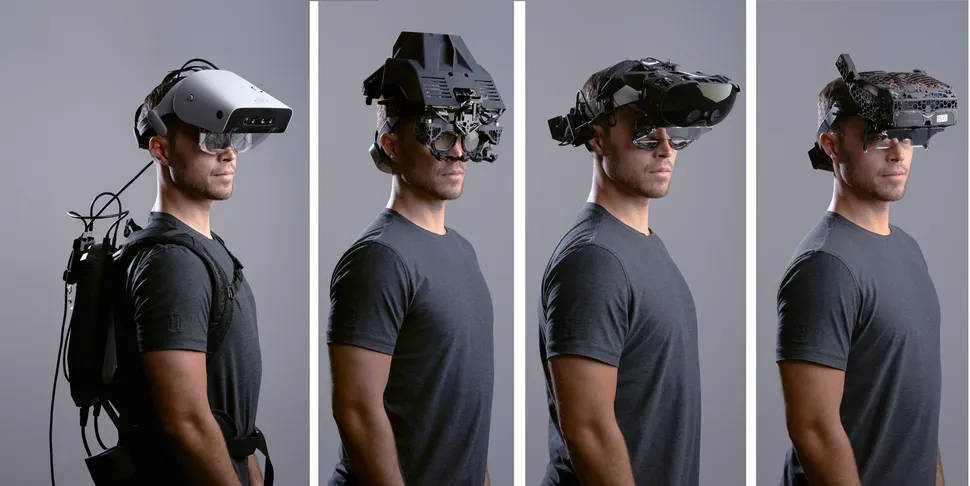

I have worked hands-on with the system integration of and demos of complete head-mounted systems with every piece of the puzzle:

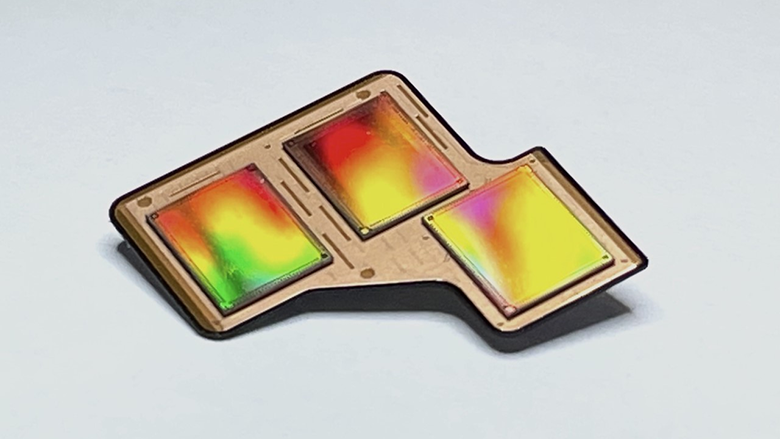

– uLED, LCoS, DLP, and laser beam scanning light engines (incl. backplanes, illumination, projection optics, active alignment, STOP analysis)

– diffractive and reflective waveguides

– ophthalmic (RX) lenses

– binocular disparity sensor

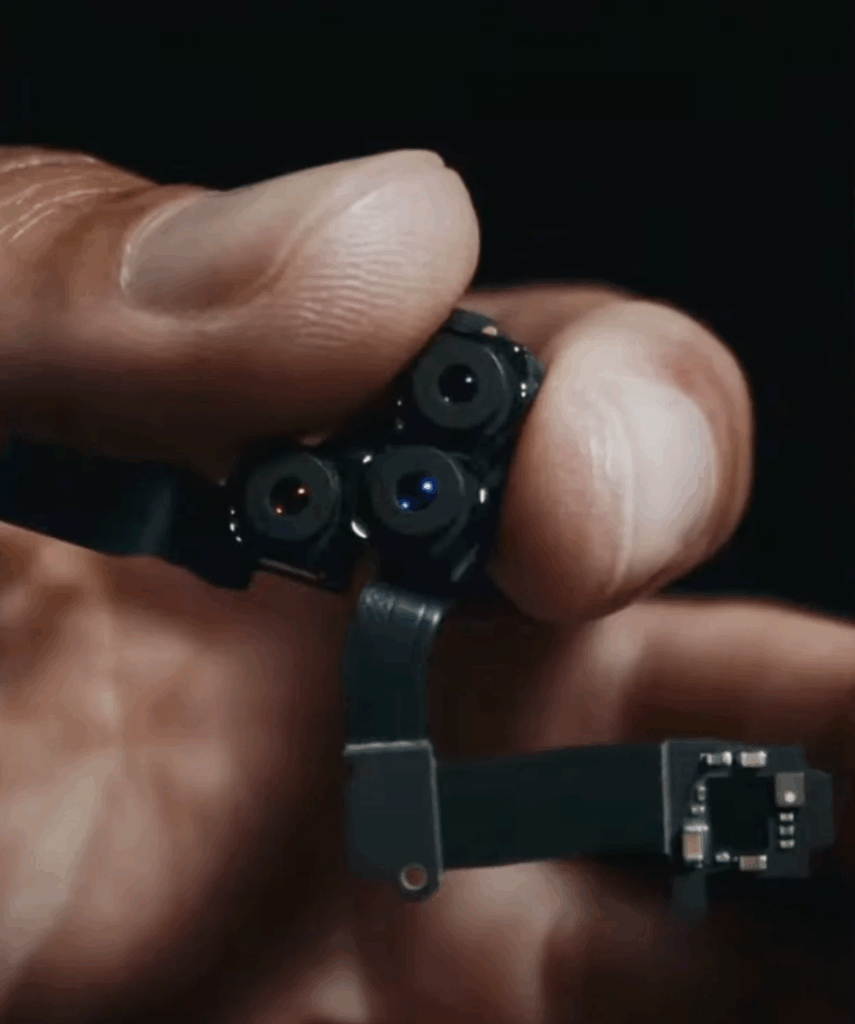

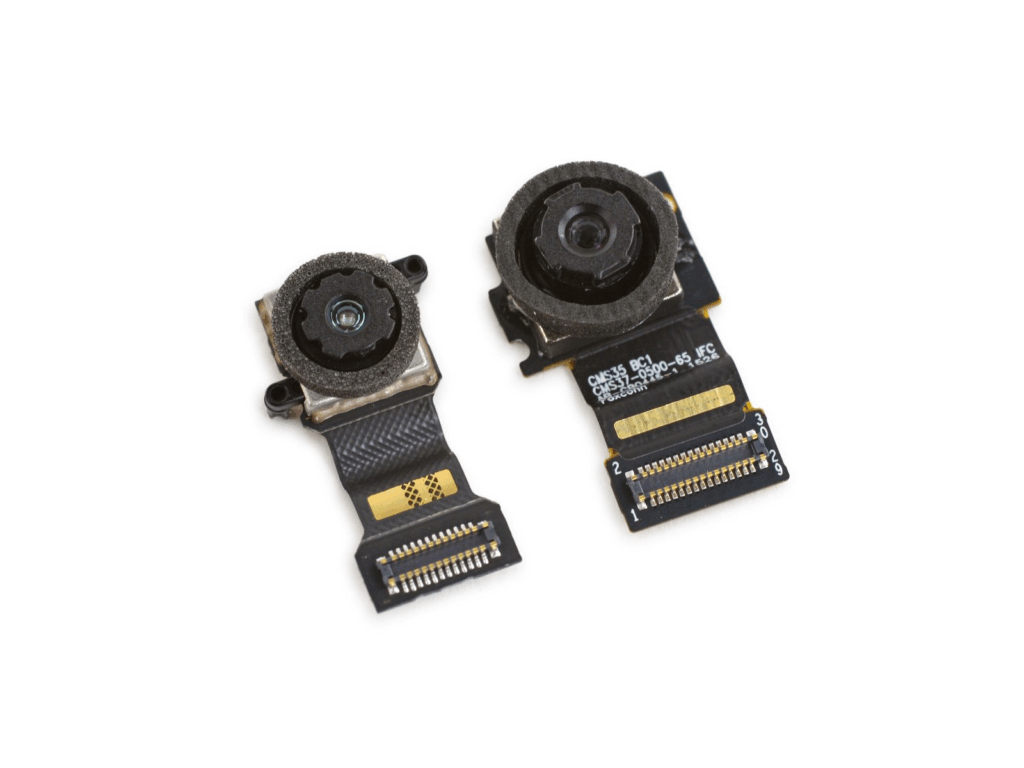

– eye tracking illuminators, combiners, and cameras

– electrochromic and photochromic dimming

– integration of the above components into modules and systems

– optical metrology equipment and methods

– geometric and photometric calibration

– perceptual evaluation and metrics

This experience allowed me to:

– create a lauded AR display 101 seminar to create a cohesive narrative for non-optics experts

– lead demos for the AR display org

– create design guidelines for how to accommodate the novel aspects of additive displays

I have invented:

– novel approaches for dynamically trading color gamut for power (brightness/battery life)

– a new integration strategy for custom ophthalmic (RX) lenses

– new use cases unlocked with AR displays